Quick fix: Oil leak from the rear differential

There comes a time in a Land Rover's life where it starts to drop oil. My 1993 200tdi will have dropped litres of fluid in its lifetime, so this latest spill is nothing new. The first thought on seeing a puddle under the vehicle from the rear differential is a faulty or worn seal. This might be the effect but not might not necessarily be the cause of the problem. There are several quick checks you can do to see what the problem might be.

For the rear differential pinion seal, which seals the input flange (connecting to the rear propshaft) from the diff internals, there is a possibility that the bearing is on its way out. This is easily checked by shaking the propshaft in all directions. If there is sizeable movement, then the bearing will have worn and movement of the flange will be damaging the seal. A new bearing and seal are required, which is covered well in this article at Reedx.

For the rear differential pinion seal, which seals the input flange (connecting to the rear propshaft) from the diff internals, there is a possibility that the bearing is on its way out. This is easily checked by shaking the propshaft in all directions. If there is sizeable movement, then the bearing will have worn and movement of the flange will be damaging the seal. A new bearing and seal are required, which is covered well in this article at Reedx.

Slightly less quick but more easily rectified is checking the axle breather. When the vehicle is moving, the differential creates an enormous amount of heat. This heats up the air inside the axle casing making it expand. Normally this vents through an axle breather pipe that extends up to the chassis, but if it is blocked then the pressure will force the oil out of the nearest seal. This could be the hub seals or in my case the rear differential pinion seal.

On expedition it is important to check these pipes at intervals to see if anything has blocked the system. A useful modification is fitting extended breather pipes so that water won't enter into the differential and is less likely to be blocked by mud.

The axle breathers vary between Land Rover models, but on my 200tdi it is a banjo bolt with copper washers and a pipe attached. I cleaned the area around the axle breather to prevent dirt falling into the axle casing and removed the bolt and pulled the pieces apart to find a gunked up hole in the bolt. The air is supposed to pass up the end and exit through the side of the bolt and into pipe.

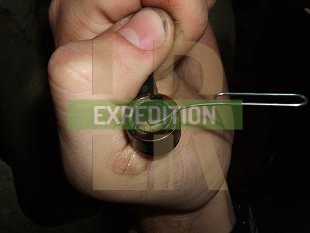

The hole into the tube was also blocked. I gave both components a soak in WD40 and scraped out the dirt with a small nail.

For the harder to reach places a paper clip was invaluable. If you blow down the higher end of the breather pipe then there should be no resistance

Fresh in the knowledge that there were now no obstructions in the breathing system, I reassembled the bolt to the casing. You have to line it up quite well to be able to screw it in.

For the moment, i've topped up the oil and the diff doesn't leak oil over the driveway after a long drive. I could have used a new breathing system, but this will see me through til I get a chance to replace the pinion seal.

The axle breathing system is an example of how simple a problem might be and how if not diagnosing the cause but treating the effects, will leave you having to do more work in the future. For the sake of a 5 minute check, it can save you having a persistent leaking differential with every seal that you replace.